At Manitek, we manufacture machined specimens for destructive testing using the exact material our clients need to validate. This approach ensures the test results accurately reflect how the material behaves in its final application.

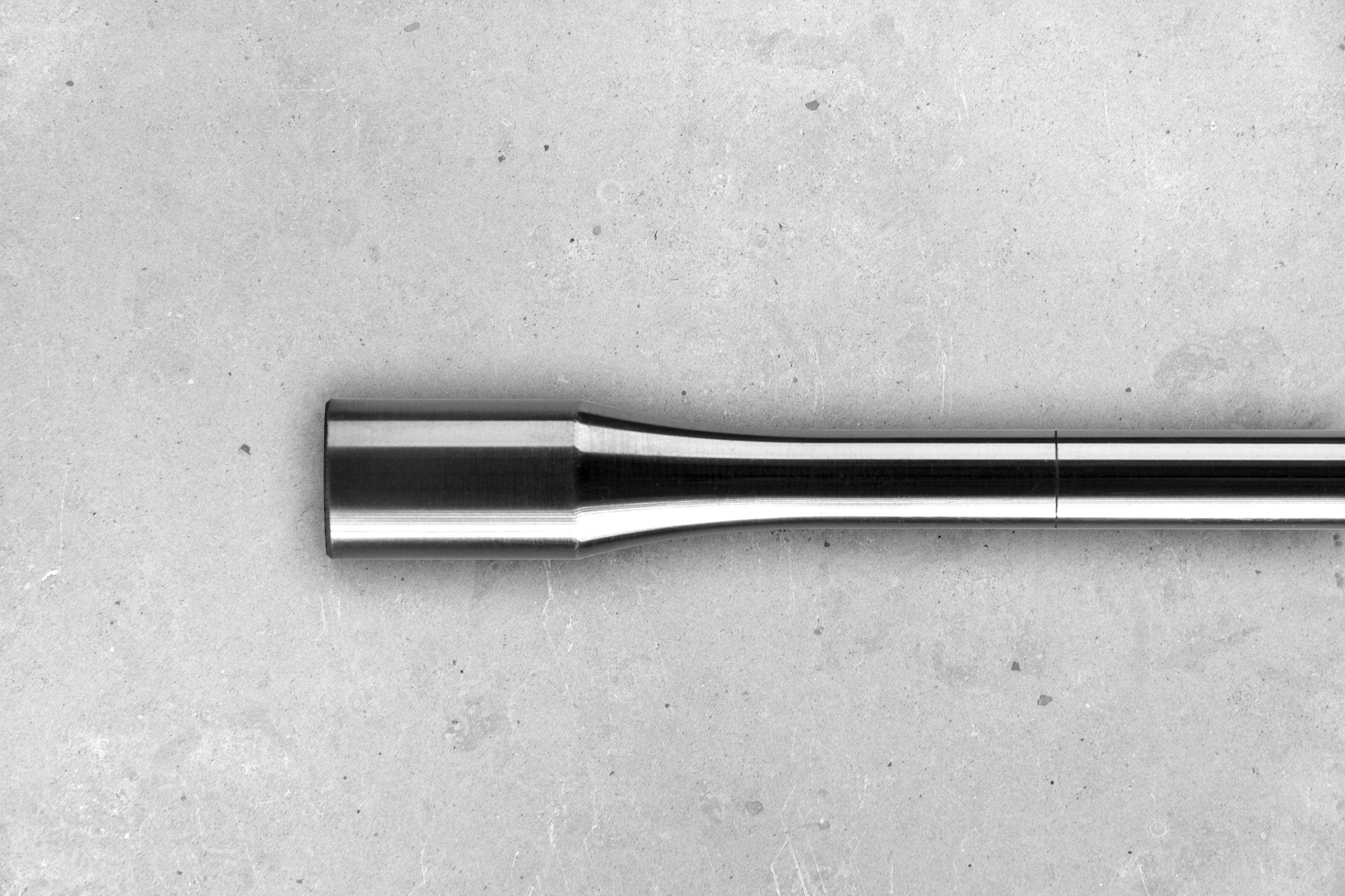

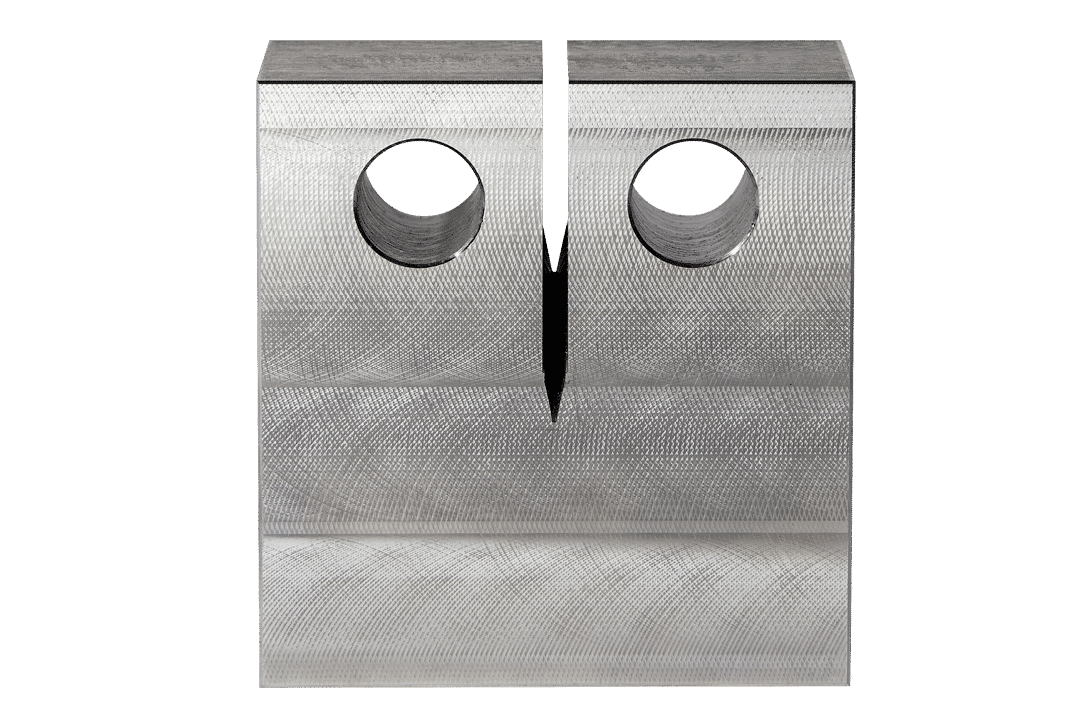

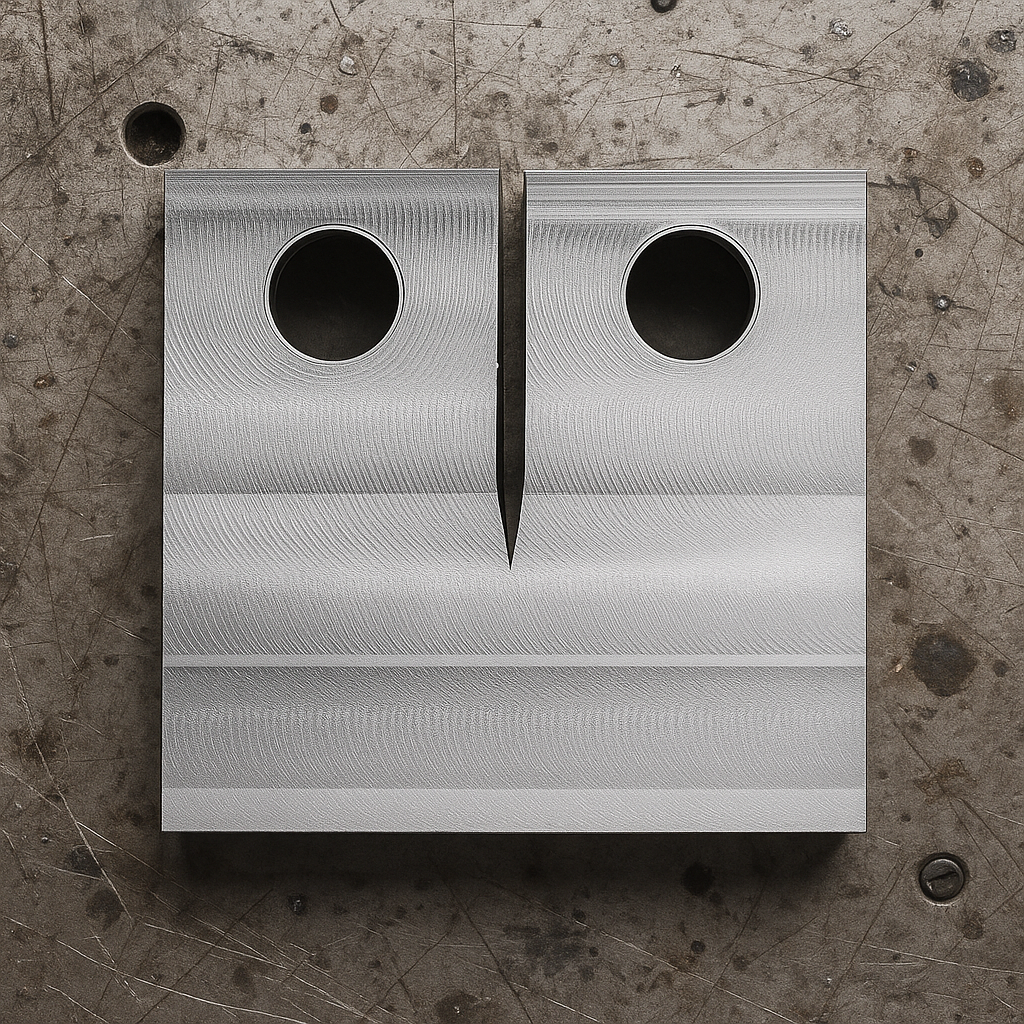

One of the most frequently used models is the K₁C specimen, employed in fracture toughness tests (mode I opening).

What is a K₁C specimen used for?

The K₁C specimen is used to determine the critical conditions that lead to the fracture of a part. During the test, variable axial tensile forces are applied to challenge the material’s resistance to crack propagation. The result allows calculation of the K₁C value, which is vital for assessing structural integrity in metals and alloys.

Real material, real results

Unlike standard specimens, our K₁C specimens are machined directly from the customer’s supplied material. This ensures the fracture test results are fully representative of the material’s actual performance.

High-precision machined specimens

- Our manufacturing process includes:

- Machining according to standards (e.g., ASTM E399)

- Controlled surface finishes to prevent unwanted crack initiation

- Full traceability of material and machining

- Tight delivery times and technical support

A key tool in industrial quality control

Machined K₁C specimens are essential for quality assurance in:

- Aerospace

- Automotive

- Energy

- Railway

- Structural engineering

Accurate testing helps reduce risk and ensure the safety and reliability of critical components.