A material does not always fail due to a single stress, but rather due to repeated loads over time. This phenomenon is known as fatigue, and it is one of the main causes of failure in industrial components.

What does it consist of?

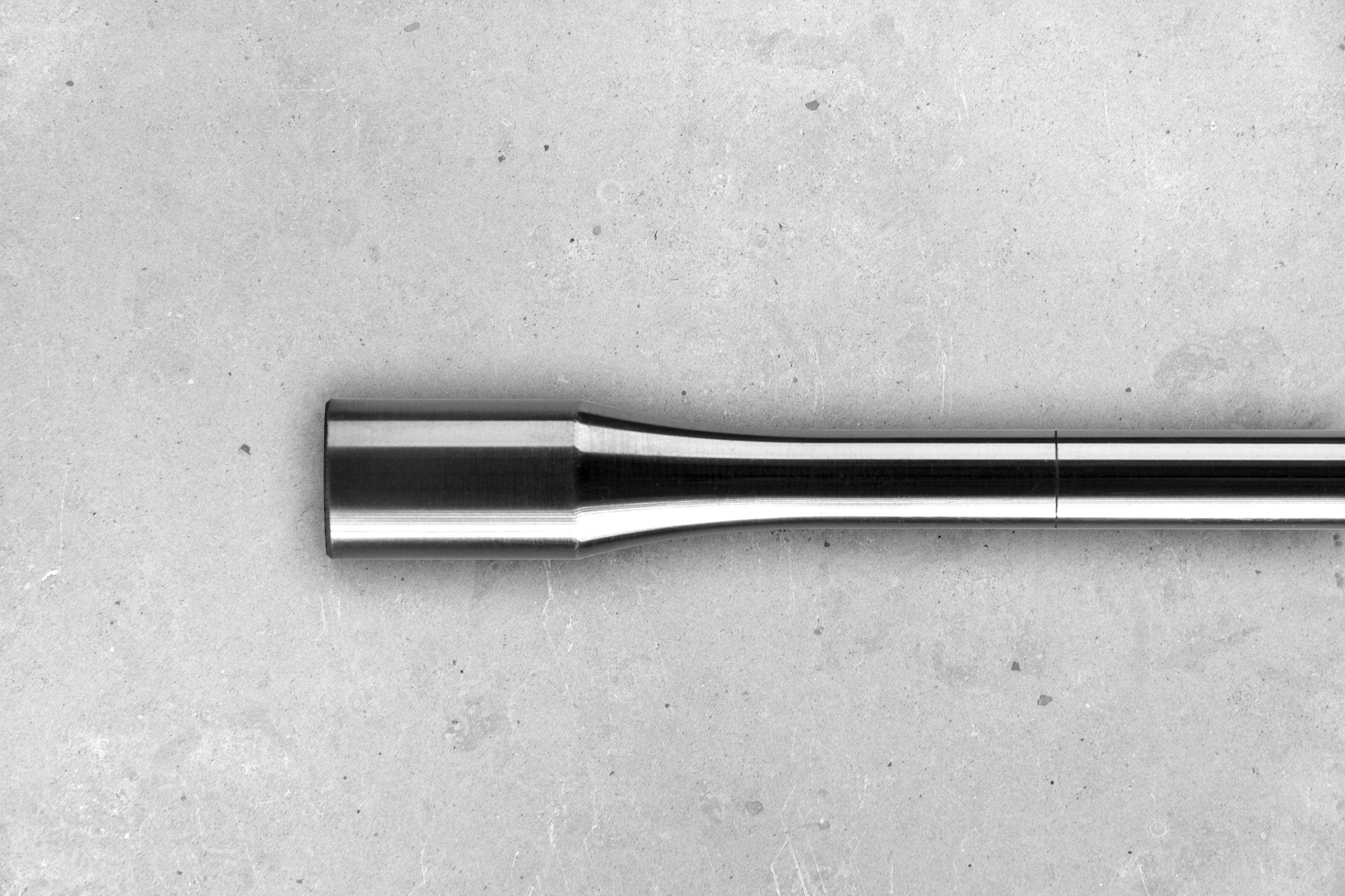

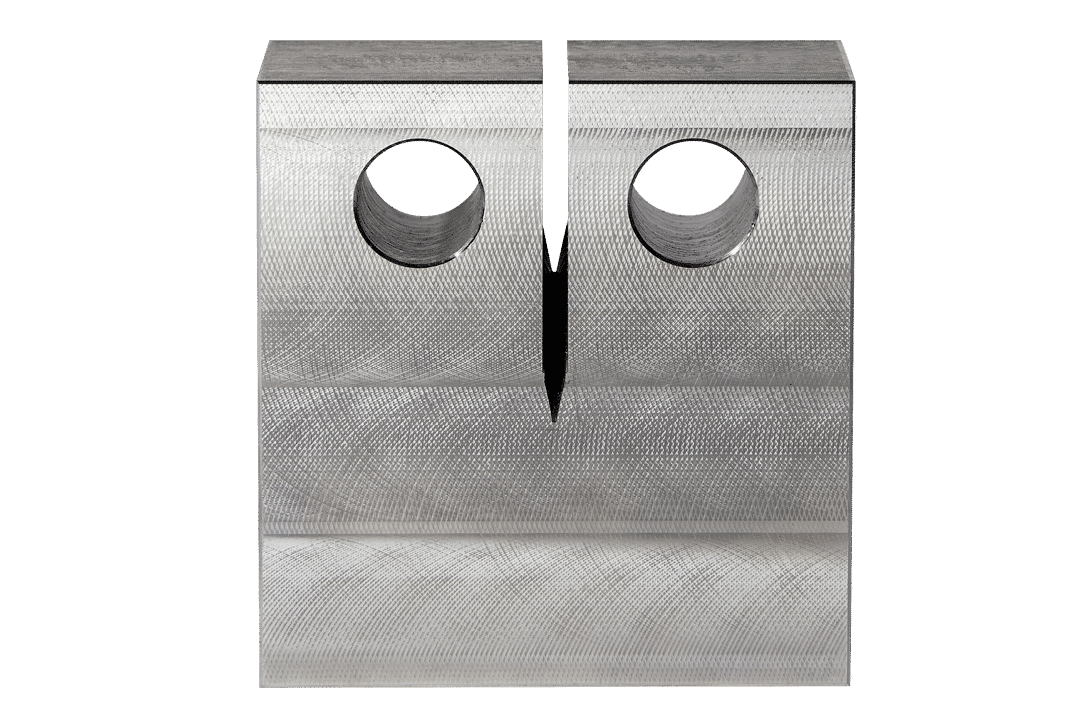

Fatigue testing consists of subjecting a test piece to a cyclic load of constant amplitude until it breaks. In this way, the service life of a material can be determined based on the number of cycles it can withstand before breaking.

This type of testing is essential in sectors such as rail, aeronautics and automotive, where components are subjected to millions of load cycles.

At Manitek, we machine fatigue test specimens with the necessary precision to ensure that laboratory results are reliable and reproducible.

Would you like to know more? Contact us for personalised advice!