LMD or Laser Metal Deposition

LMD or Laser Metal Deposition is an innovative system for additive manufacturing, a manufacturing method that is now being implemented across our business sector and is now emerging as an industrial revolution in many different sectors.

Additive manufacturing technology is based on manufacturing components by adding layers of material based on a model developed in 3D CAD by using a highly concentrated energy source.

What are the main benefits of additive manufacturing?

– Manufacture of new shapes and structures that were previously unthinkable.

– Extraordinary use of material.

– Repair of high added value parts.

– Multi-material construction.

– Quick manufacturing from product conception as there is no need to manufacture specific tooling or peripherals.

– Profitability from short production runs and prototypes.

– Product customisation.

LMD in tool repairs.

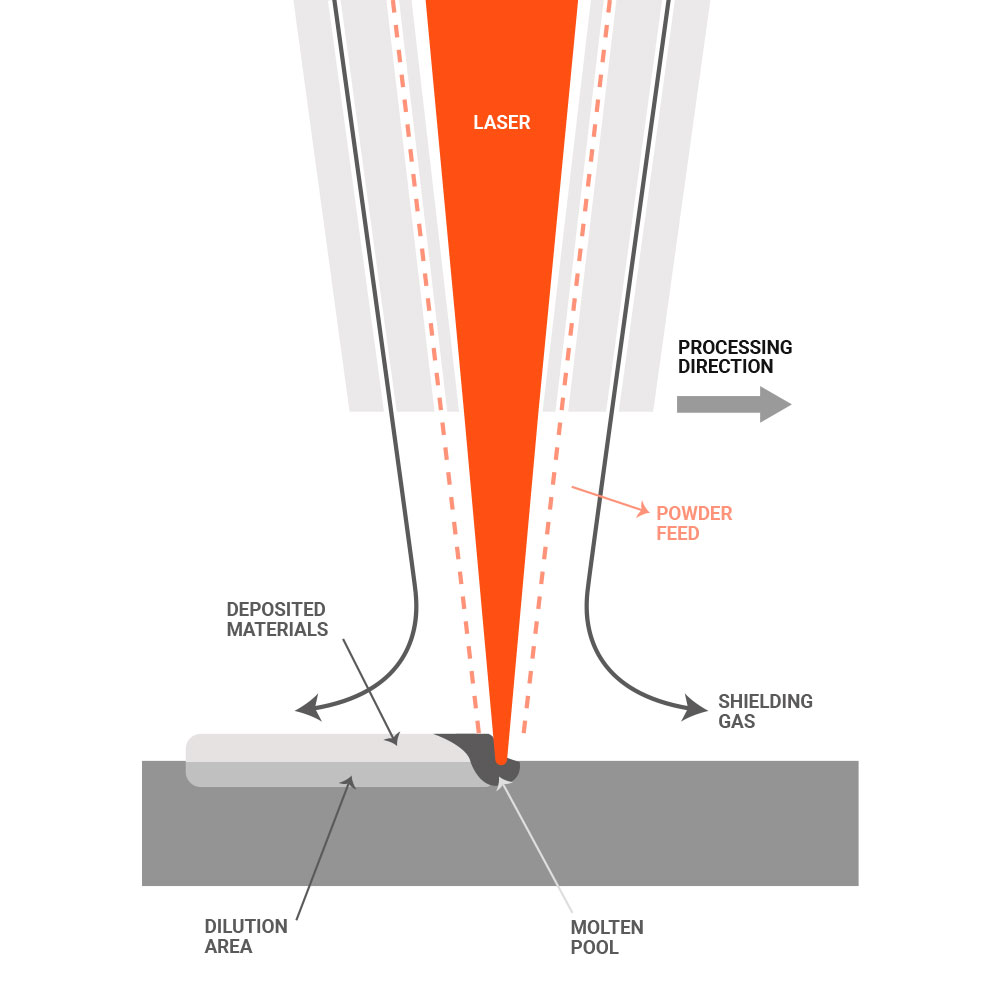

Laser is the energy source in this process, generating a concentrated beam that melts the metal, which is applied precisely via a nozzle.

There is a wide range of materials and alloys to use with this method, making it possible to choose the most viable material for each tool and use.Repairing and reconstructing cutting tools with this method brings great added value and significantly prolongs their service life, thus helping to optimise resources.

Another great benefit of this method is the optimal use of raw materials. Only the material required for a specific area is melted, thus reducing waste and excessive consumption of raw materials.

Manitek is involved in a development and optimisation project for this tool, aimed at allowing it to be integrated into our cutting tool restoration production process in the future.